A comprehensive CAD software

suite for the design and manufacture of Electrical Wiring Interconnection Systems (EWIS)

Designed for aerospace and other mission critical equipment

HarnesSYS is a comprehensive software suite that facilitates functional, logical and physical harness design for complex electrical systems in aerospace and other industries.

Harnessys incorporates the benefits of an intuitive and convenient graphic editor with centralized data management ensuring data integrity and traceability across multiple systems and vehicle configurations.

- DESIGN

- INTEGRATE

- MANUFACTURE

Design by System

Manufacture by Harness

Aircraft harness design and maintenance is done per electrical system, while allocation of wiring to different harnesses is done based on physical constraints. Therefore, wiring harnesses typically contain wiring from multiple systems.

HarnesSYS manages this complexity by automatically capturing the design data from the various system diagrams and storing it in a central database. This data is then used to automatically compose a full set of harness manufacturing documents.

Robust Design

HarnesSYS incorporates design checks and verifications throughout the design process. It is specifically designed to handle sophisticated and complex systems, ensuring a robust design the first time around, and preventing costly rework and schedule delays.

Vehicle Configuration Management

Aircraft platforms last for decades, and the electrical installation differs from vehicle to vehicle. HarnesSYS manages the electrical design per system so that it is easily interchangeable, and harnesses are updated automatically.

Version Control

HarnesSYS includes built-in version control and change management which interfaces with the company’s PDM.

New designs can be compared to previous ones for effortless design change tracking.

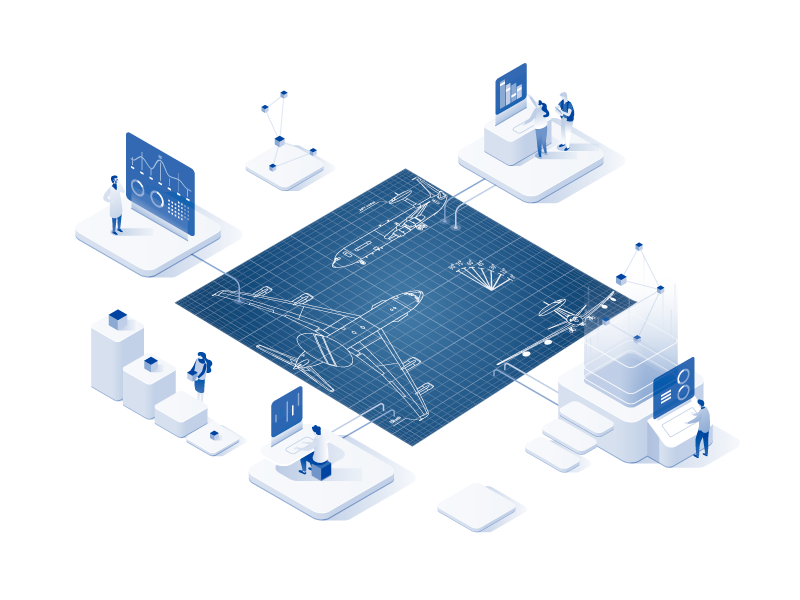

Model Based System Engineering

When information is passed manually from one domain to another it is inefficient, and potentially error prone. In a model-based engineering flow, data is created once and is accessed by all engineers and professionals collaborating on the project throughout the different stages of the product lifecycle. Devices and networks can be designed by system engineers within HarnesSYS or imported from other software into the HarnesSYS database.

Centralized Data Management

HarnesSYS incorporates the benefits of an intuitive and convenient graphic editor with centralized data management ensuring data integrity and traceability across multiple systems and vehicle configurations. With the centralized database storing all part, wire and connection data, multiple users working simultaneously on complex projects can be confident of design consistency.

Electrical and Mechanical

Design Collaboration

Designing an aerospace platform’s electrical system requires close collaboration between mechanical engineers designing the platform’s physical routing and electrical engineers designing the actual wiring interconnections. Seamless integration of HarnesSYS within CATIA or NX facilitates data sharing throughout the design process, promoting the efficient design of electrical systems.

Industries

AIR

LAND